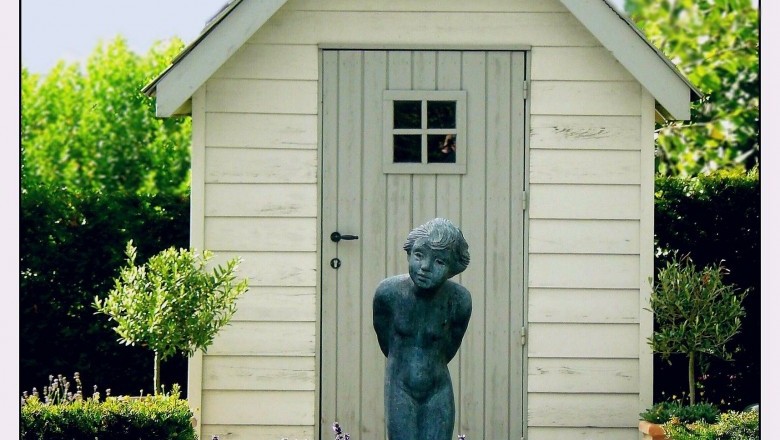

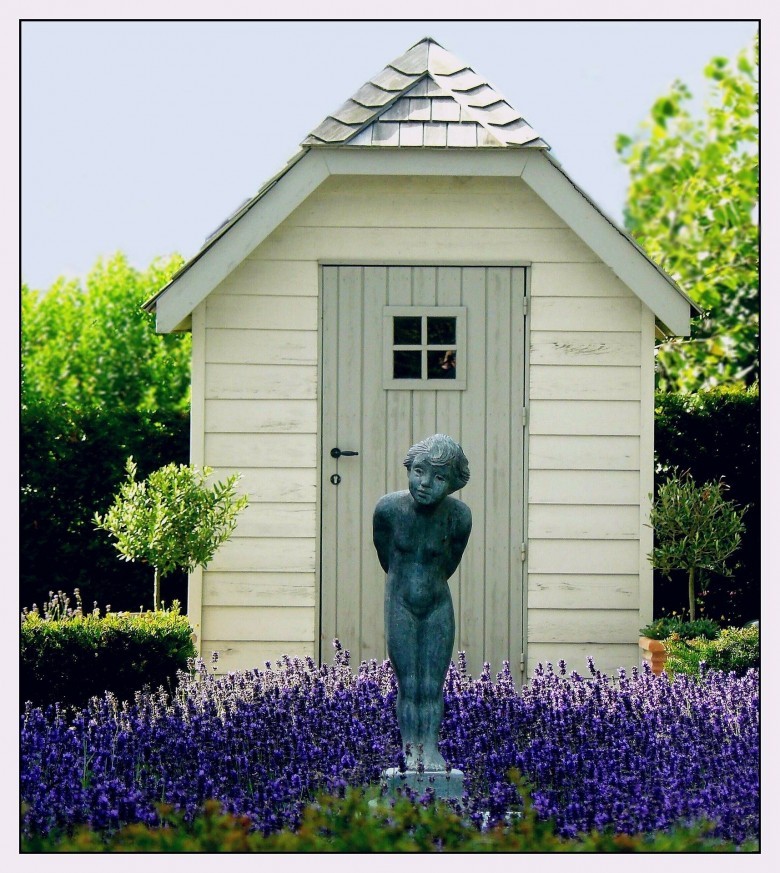

Shed Kits

Many people want to build their own shed but dont have the time to put into it or the skill level to build it from scratch. A solution to this problem is shed kits. Shed kits are pre-designed sheds that come to your home in pieces consisting of sidings, panels, doors, windows, floors, and roofs that must be reassembled on site. Why would you want to purchase a shed kit instead of a full shed? There are several reasons, the first being that having a pre-built shed delivered to your house is much more expensive. Also, you will likely have to hire a team to load and unload the shed. If you dont want to have a full shed delivered, you could hire a team of carpenters to come and build the shed for you, but this also costs a lot of money.

Some shed kits can be dismantled as easily as they can be assembled, which is a great advantage when people decide to move.

Shed kits come with all the components that are needed to make a shed. Most shed kits can be assembled using simple tools. Typically shed kits do not require carpentry skill and are designed so any person can assemble them by following well documented instructions. Once the site is prepared and the foundation is constructed, most shed kits, depending on their size, can be assembled in a day.

There is a wide array of shed kits available in all styles and sizes that are the most commonly used. Sizes usually range from the 3 x 2 to 14 x 31. Small sheds commonly have a single door and a lower ceiling while large sheds usually have double doors; which makes loading and unloading large equipment much easier. Some of the larger sheds also offer garage style doors which are easier to open and close in the winter months. Shed kits come in many styles, including

greenhouses, storage sheds, metal sheds, steel sheds, plastic sheds, vinyl sheds,

wood sheds, etc. Of course, no matter what size or style you get, you can choose different roof and window styles to customize your shed. Prices vary depending on shed style and size. Of course, the larger and fancier the shed, the more expensive it becomes.Many manufacturers of shed kits offer a variety of accessories including shelving, windows, shutters, window boxes, skylights, lights, and anchor kits to fasten the shed to the ground. Since some of the shed kits do not come with floors, another common accessory is foundation kits.

Shed foundation kits are useful in that they speed up the process of building the shed floor. Another advantage of foundation kits is that quite often they are made of galvanized steel which is more durable than if you opt to build your own shed foundation out of wood. Additionally shed foundation kits tend to save you money since they generally cost less than lumber. Metal sheds and steel sheds are the more difficult to assemble than other types of sheds. They need a lot of screws to be fitted in and many screws wont fit exactly in other places and so they demand a lot of patience.

Metal sheds are a very durable type of shed, provided the metal is rustproof. Galvanized steel is one example of a material which will resist rusting. Some shed kits have a vinyl coating over the paint which also extends the life of the shed. Metal sheds require maintenance if the paint surface is scratched. Pay attention to the length of the warranty since metal sheds may begin to rust once they have aged beyond the warranty period. If you need a portable shed that can be readily dissembled and moved to another location, you should consider a shed made out of different materials other then metal or steel. Once metal sheds or steel sheds are put together they cannot be taken apart so. Plastic sheds and vinyl sheds are much easier to assemble than metal sheds.

Another advantage of plastic and vinyl sheds is that they are maintenance free. They do not require painting or staining and will not rust, rot, or mildew. Many plastic and vinyl sheds are designed to be portable sheds which can be readily disassembled. Also some plastic and vinyl sheds are designed so that if your storage needs grow, you can purchase shed extension kits to increase the size of your shed. The main problem with plastic and vinyl sheds is with the weight, which creates a higher chance of the shed getting uprooted in heavy winds. Vinyl sheds and plastic sheds should always be anchored down to some kind of foundation.

Wood sheds kits are usually more expensive than other sheds. Their prices fluctuate depending on the quality of wood. Good quality cedar wood sheds are usually the most expensive, but the highest quality. Wood shed kits tend to be heavier than metal, plastic, or vinyl sheds. As a result they tend to cost significantly more to transport. The larger the shed, the more difficulty you will have in lifting the walls, roof, and floor components off the delivery truck. Another drawback to wood shed kits is that you need carpentry expertise in order to assemble them. If you buy a wood shed kit, plan on doing lots of maintenance. The shed walls will need to be painted or stained on a regular basis to prevent rotting and insect damage. Periodically you will also need to replace the shingles on the roof.

Before ordering a shed kit, a person should find out whether there is any restriction to building a shed in the neighborhood, or it will just be a waste of money.Your local community building commission should be able to answer this question as well as letting you know if a building permit is required.Michael Cook is a marketer for Shedtopia. For more information about Shed Kits, visit shedtopia.com.